- Our catalogue

- ...

- Mixer units

- VALTEC TECHNOMIX pump mixing shunt for floor heating

VALTEC TECHNOMIX pump mixing shunt for floor heating

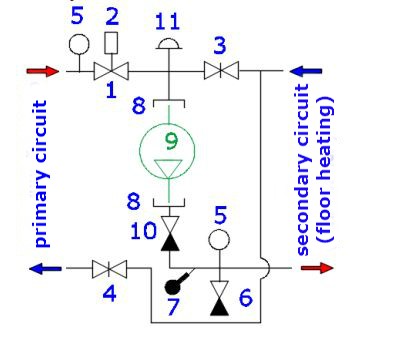

(VT.TECHNOMIX.0) The VALTEC TECHNOMIX pump mixing shunt is designed to create an open circulation contour in the heating system of a building with a temperature lowered in accordance with the values set. The shunt maintains the specified temperature and flow in the secondary circulation loop, and allows you to adjust the temperature and the flow of the thermal media based on user requirements.

The Technomix pump mixing shunt is typically used in integrated heating (floor heating, walls heating, open-area heating, greenhouses heating, etc.).

The shunt can work with distribution manifolds of the floor heating hinges at the center-to-center distance between manifolds of 200 mm. The shunt is supplied without a circulating pump.

The mounting length of the pump shall be 130 mm (you can use, for example, VRS 25/4G-130; VRS 25/6 G-130 models).

The dimensions of the mixing shunt allow it to be placed in the VTc.541.D manifold closet (depth: 135 mm).

The shunt can be installed both to the left and to the right of the manifold unit.

Symbols on the picture: 1 – thermostatic valve; 2 – thermal head with an extension sensor or servoactuator (servoactuator is not included in the package); 3 – secondary loop balancing valve; 4 –primary loop balancing valve; 5 – thermometer; 6 – clearing plug; 7 – temperature sensor cartridge; 8 –captive nuts for pump attachment with gaskets; 9 – circulation pump (not included in the package); 10 – return valve; 11 – manual air vent.

VT.TECHNOMIX can operate via VT.K200.M weather-based controller. In this case, instead of the thermal head with an extension sensor, VT.TE3031 analogue electrothermal servoactuator shall be mounted on the thermostatic valve.

VT.TECHNOMIX pump-mixing shunt and all its components are produced in Italy.

| Article | Size / number of | Price per unit |

|---|---|---|

| VT.TECHNOMIX.0.130 | 200 mm, 130 mm | 31217 ₽ |

| * Prices shown are recommended retail prices by the manufacturer | ||